High Precision Transmission is Stable andReliable.Inner Cam Track control can provide longservice life.Extremely High Production Capacity,withhigh filling procision.

| Capacity: | 2000-3500 Grains/minute |

| Segment pin number: | 24 Double line |

| Suitable capsule size: | 00#~5# |

| Filling precision: | ±2% |

| Working noise: | ≤70dB |

| Power: | 7KW |

| Dimension LxWxH: | 1400x1300x2000mm |

| Net weight: | 1800KG |

After the production experience of thousands of capsule filling machines, the latest HG-1000A has been developed to work more efficiently and steadily.

Many innovative operations and safety features simplify the production process and provide a processing speed of up to 50,000 capsules per hour.

The capsule filler can handle all capsule sizes from 000 to 5. A special design allows to change different size capsules easily, simply and accurately within 15 minutes.

It can be filled with powder, pellets or granular materials. The Capsulcn laboratory has tested it and there is no failure within 600,000 minutes.

| Capsule size: | 000#,00L#,00#,0L#,0#,1#,2#,3#,4# |

| Capacity: | 40,000 to 50,000 per hour |

| Total measurement: | Length: 1140 mm Width: 700 mm Height: 1630 mm Weight: 400KG |

| Package Size: | Length: 1650 mm Width: 800 mm Height: 1750 mm Weight: 500 kg |

Its transmission system are used gearbox driving.This model has several features,suchas small dimension, low noise,whichwould be the perfect choice for small or medium pharmaceutical companys,hospitals,and loaboratories, etc.

| Capacity: | 200-1200 grains/min |

| segment pin number: | 9 holes |

| Suitable capsule size: | 00#~5# |

| Filling precision: | ±2% |

| Working noise: | ≤70dB |

| Power: | 5KW |

| Dimension LxWxHl: | 800x970x1870mm |

| Net weight: | 850KG |

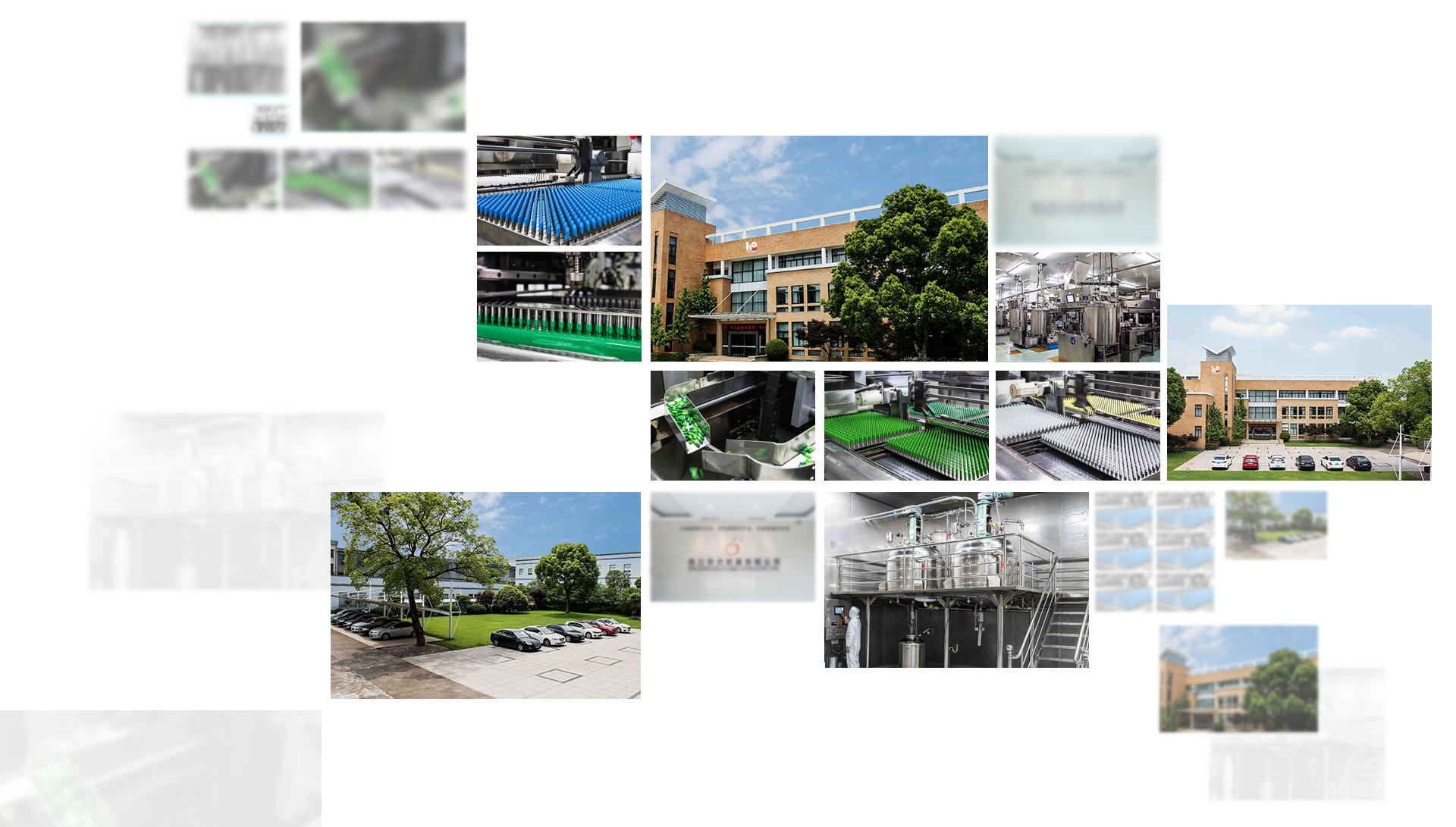

We are located in Zhejiang Province, where is near the international city of Shanghai. HGcaps has the land of over 370,000 square feet with an advanced GMP(NSF) factory of 100,000 square feet and 30 automatic capsule production lines, which can produce 20 billion hard empty capsules per year.

HGcaps believes in developing science and technology could make our OEM wholesale Capsule Filling Machine more Competitiveness. Also, HGcaps has combined the vacuum material transfer system, intelligent weighing system, visual scanning inspection system, AGV transportation system, MES, and SAP into a new smart factory to ensure our Empty Capsule Equipment Machine have stable and high quality.